Effect of Substrate Roughness on Friction and Wear Properties of Cr-DLC Films under Dry-Sliding Condition

-

摘要: 采用磁控溅射/等离子辅助气相沉积方法在不同粗糙度样品表面制备Cr掺杂类金刚石(Cr-DLC)薄膜, 研究了干摩擦条件下, 基体粗糙度对Cr掺杂类金刚石薄膜摩擦磨损性能的影响. 结果表明: 在低表面粗糙度样品上体现了Cr掺杂类金刚石薄膜良好的自润滑特性, 平均摩擦系数在0.1以下, 达到了油润滑条件的摩擦水平, 磨损较小, 磨损表面薄膜结构完整, 未出现明显石墨化转变. 在高表面粗糙度样品上, 样品的平均摩擦系数提高了3~4倍, 磨损剧烈, 基体表面磨出了明显的沟槽, 与其对摩的Si3N4球磨损严重.

-

关键词:

- 磁控溅射/等离子辅助气相沉积 /

- 不同基体粗糙度 /

- 干摩擦 /

- Cr掺杂类金刚石薄膜 /

- 摩擦磨损性能

Abstract: Cr doped DLC films were prepared on samples with different roughness by magnetron sputtering/plasma assisted vapor deposition. Effect of the substrate roughness on friction and wear properties of Cr doped DLC film under dry-sliding condition was studied. The results show that the Cr doped DLC film on sample with low surface roughness exhibited good self-lubrication properties. The average friction coefficient was below 0.1, which was comparable to that under oil-lubricating condition. Meantime, the mild wear and the film structure on worn surface was well preserved without significant graphitization. However, the average friction coefficient was raised by 3–4 times on samples with high surface roughness. The wear was severe and wear surface included obvious grooves and severe wear of the coupled Si3N4 ball. -

类金刚石薄膜(DLC)是介于金刚石和石墨之间含有sp3和sp2杂化键的亚稳态薄膜, 其有很多表现形式包括非晶态薄膜, 硬质碳薄膜等[1]. 类金刚石薄膜具有很多与金刚石薄膜相似的优异性能, 如高硬度、低摩擦系数、耐磨损、抗划伤性、耐腐蚀性、抗粘连性、高化学稳定性、良好的光学透过性和优异的生物相容性, 其作为新型功能材料在机械、工模具、刀具、汽车、电子、光学、生物医学以及航空航天等众多领域都有极大的应用前景[2–7]. 在对类金刚石薄膜的研究和实际应用中, 人们发现类金刚石薄膜的内应力较高、韧性差、脆性高, 导致薄膜与基体的结合能力差, 薄膜使用寿命短. 为解决上述问题, 研究人员通过在类金刚石薄膜中掺入异质元素[6]来改善薄膜的综合性能. 研究[8–13]表明: 选择合适的掺杂元素不仅可以有效降低薄膜的高应力, 而且可以改善薄膜的机械摩擦学性能. 常用的掺杂物质包括金属、非金属和化合物, 其中金属掺入类金刚石薄膜中, 掺杂金属能以原子固溶、纳米晶或金属碳化物等多种纳米结构非均匀地镶嵌在非晶碳基交联网络中, 形成典型的纳米晶/非晶复合结构, 增强薄膜的机械强度和韧性.

金属Cr具有优异的耐磨性和较强的抗氧化能力, 同时能与钢基体良好的结合. Cr作为掺杂元素引入非晶碳基质中, 能够有效缓解薄膜内应力和提高膜基结合力, 改善DLC薄膜的高应力、高脆性和摩擦学性能[14–18]. Cr掺杂DLC薄膜是金属掺杂DLC薄膜中研究的热点和重点之一, 主要的研究方向集中在Cr掺杂量不同对薄膜摩擦学性能的影响、制备工艺参数(如偏压、靶电流等)对薄膜摩擦学性能的影响以及不同测试条件下Cr掺杂DLC薄膜的摩擦学性能等.

理论上来说, 一定的表面粗糙度对提高薄膜与基体的结合力有帮助[19–22]. 尽管Cr掺杂DLC薄膜显示出良好的摩擦磨损性能, 但不同粗糙度对Cr掺杂DLC薄膜摩擦磨损性能研究并不充分, 特别是对Cr掺杂DLC薄膜干摩擦条件下自润滑摩擦磨损性能的影响研究尚有不足. 因此, 本文中采用多功能离子镀膜系统, 在不同原始表面粗糙度的耐蚀不锈钢试片表面制备Cr掺杂DLC多层薄膜, 系统研究了基体表面粗糙度的差异对Cr掺杂DLC多层薄膜的摩擦学性能的影响.

1. 试验部分

1.1 基体处理

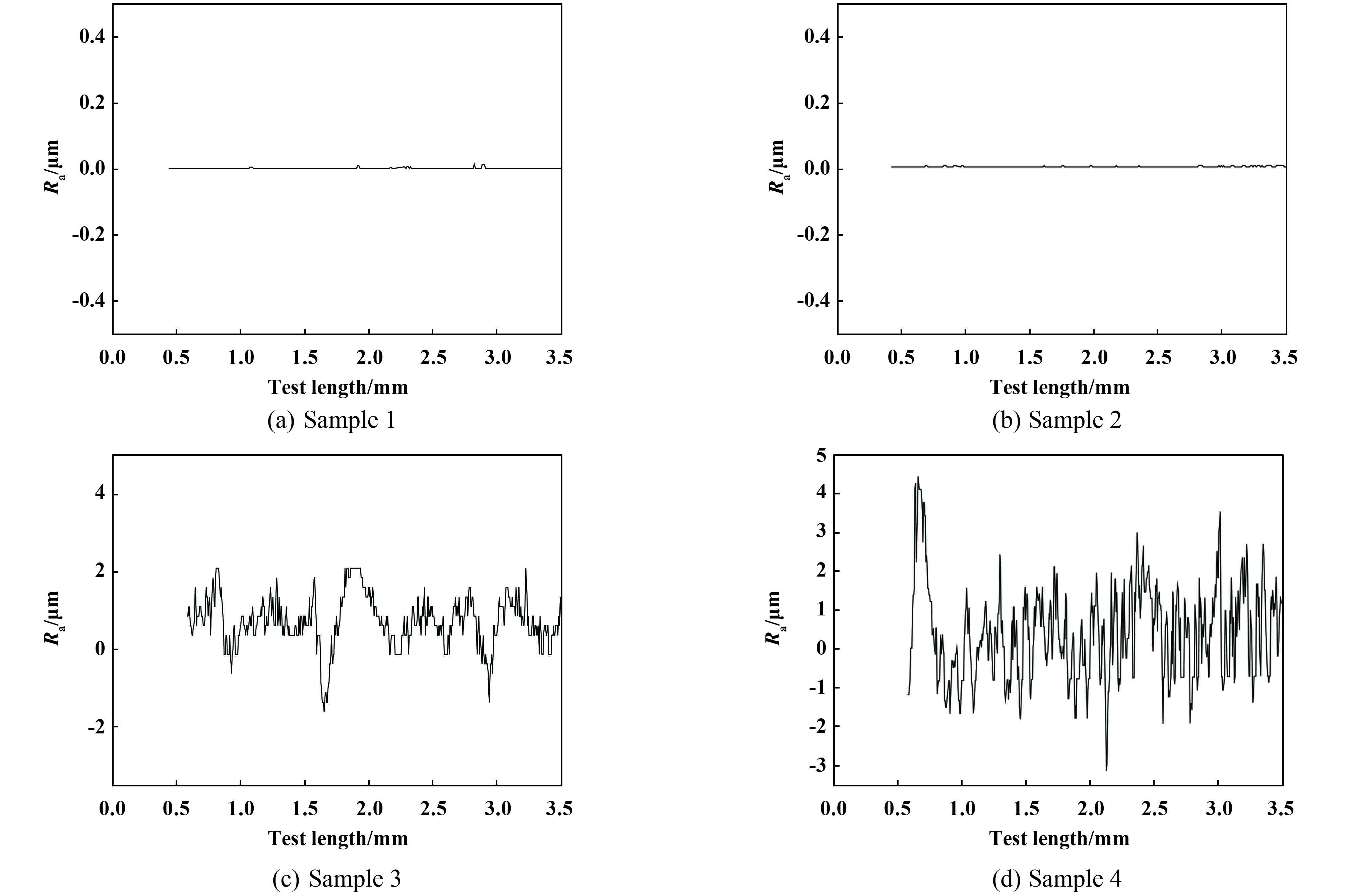

试验对象为φ30 mm×10 mm的耐蚀不锈钢试片. 采用不同的处理方法获得4类不同的表面粗糙度: (1)采用手动式磨抛机, 2 000#砂纸磨光后进行抛光处理, 样品平均粗糙度Ra为0.015 μm; (2)采用手动式磨抛机, 1 500#砂纸磨光, 样品平均粗糙度Ra为0.025 μm; (3)采用虹吸式手动湿式喷砂机, 磨料为400目白刚玉, 样品平均粗糙度Ra为0.56 μm; (4)采用自动精磨机床, 样品平均粗糙度Ra为0.786 μm. 用手持式粗糙度测试仪测量样品的表面粗糙度曲线如图1所示.

1.2 薄膜制备

薄膜沉积设备为自制多功能离子镀膜系统, 该系统可实现多种镀膜技术(诸如阴极电弧、非平衡磁控溅射和等离子增强化学气相沉积)的复合使用. 该设备配置柱状非平衡磁控溅射Cr靶, 纯度为99.99%, 用于过渡层CrN的沉积和掺杂Cr元素的类金刚石工作层的沉积; 1个矩形封闭气体离子源, 一方面可以通过离子源离化惰性气体对工件表面进行清理, 另一方面也可以离化工作气体(CH4)用于掺杂类金刚石膜的制备. 系统配套使用的气体包括纯度99.999%的氩气和99.9%的甲烷气体.

采用七槽工业清洗机进行多工序超声波清洗共30 min, 清洗吹干后放入80 ℃的烘箱内进行烘干. 烘干后放入真空室, 抽真空至5×10–3 Pa, 通氩气至5×10–1 Pa, 用离子源结合偏压溅射对试片表面进行等离子体清洗去除表面氧化层; 当真空度达到3×10–1 Pa时开始薄膜制备, 薄膜制备的工艺参数如表1所示.

表 1 Cr-DLC薄膜制备工艺Table 1. Deposition condition of the Cr-DLC filmCoatingprocess Coatingtemperature/ ℃ Total gaspressure /Pa Gas Time/min Plasma cleaning 100 1 Ar 60 Adhesion layer 150 0.3 Ar+N2 60 Inter layer 150 0.4 CH4+ N2 90 Cr-DLC layer 130 0.4 CH4 150 1.3 性能表征方法

采用S-4800型冷场发射扫描电子显微镜对Cr-DLC薄膜的截面形貌、膜层厚度进行测试分析. 采用TR-200型手持式粗糙度仪对镀膜前后材料的表面粗糙度进行测试, 设定取样长度0.8 mm. 采用LabRAM HR Evolution型高分辨拉曼光谱仪对薄膜的微观结构进行测试分析, 选用514 nm激光器激发, 束斑直径1.25 μm, 功率150 μw/cm2, 扫描时间60 s, 累加次数1次. 采用MFT-4000型多功能材料表面性能试验仪测试膜基结合力, 终止载荷设定为100 N, 加载速率100 N/min, 划痕长度5 mm. 采用MS-T3000型摩擦磨损试验机, 以φ4 mm的Si3N4球为对摩材料, 设定摩擦线速度为0.2 m/s, 行程为1 000 m, 加载力 2 N, 试验在室温环境下进行. 采用Phase Shift MicroXAM-3D三维白光干涉表面形貌仪对摩痕形貌和磨痕长度、宽度进行分析.

2. 结果与分析

2.1 薄膜的组织结构和力学性能

Cr-DLC薄膜的采用梯度多层结构总厚度为2.61 μm, 如图2所示. 可以看出采用截面法和球坑法获得的薄膜厚度基本一致, 其中粘结层CrN, 厚度约为0.79 μm; 中间层CrN/CrCN, 厚度约为0.68 μm; 工作层Cr-DLC, 厚度1.14 μm.

如图3所示, 采用拉曼光谱对Cr-DLC薄膜结构进行了分析, G峰的峰位在1 541 cm–1处, D峰的峰位位于1 350 cm–1处, 同时计算获得ID/IG的比值约为1.46.

薄膜与基体的结合力是评价薄膜的一项主要指标, 结合力的高低对薄膜摩擦磨损性能的好坏也起到重要的作用. 膜基结合力的测试结果如图4所示, 4个样品膜基结合力分别为68、65、60和62 N. 随着基体粗糙度增加膜基结合力略有下降, 但降幅并不明显.

2.2 镀膜对基体表面粗糙度的影响

薄膜生长, 不同晶面的优先取向会导致表面粗糙度产生很大差别. DLC薄膜由于其无定形的内在属性使得取向优先生长导致粗糙度增加的过程不会发生. 虽然不同的沉积方法和工艺会造成一定的粗糙度差别, 但DLC薄膜具有沿基底表面生长的特性, 最终的粗糙度会与基体相近. 如图5所示, 镀膜后样品的平均表面粗糙度分别为0.018、0.031、0.484和0.882 μm, 与镀膜前粗糙度基本相当.

2.3 基体粗糙度对摩擦系数的影响

4种不同表面粗糙度的样品, 在相同的载荷、转速条件下, 分别进行了干摩擦和油润滑摩擦磨损试验. 在干摩擦条件下, 如图6(a)所示, 样品的平均摩擦系数分别为0.083 4、0.095 1、0.349 0、0.413 2. 在油润滑条件下, 如图6(b)所示, 样品的平均摩擦系数分别为0.083 7、0.087 1、0.096 3、0.095 4. 可见, 基底粗糙度差异引起镀膜后表面粗糙度差异, 进而对薄膜在干摩擦和油润滑条件下摩擦系数产生了不同的影响. 干摩擦条件下, 4种样品的摩擦系数表现出了明显的差异, 1、2号样品的摩擦系数比较平稳, 始终保持在0.1以下, 3、4号样品的摩擦系数表现为先升高再回落后逐步平稳, 4号样品的粗糙度最高, 其摩擦系数从升高到回落、稳定的时间更长. 总体上, 粗糙高的3、4号样品比粗糙度低的1、2号样品的摩擦系数提高了3~4倍, 低粗糙度样品更好的体现了Cr-DLC薄膜的自润滑特性. 这主要是由于粗糙度增加意味着样品表面不平整性增加, 从而使得摩擦接触面在相对运动时候机械咬合作用增强, 进而使得摩擦接触面相对运动阻力增大. 这也说明Cr-DLC涂层在粗糙度较低时候自润滑性能得到了充分展现, 而在粗糙度较高时会受机械咬合作用增强影响使得自润滑效果逐渐减弱. 在油润滑条件下, 4种样品摩擦系数总体相差不大, 平均摩擦系数都在0.1以下, 随着粗糙度增加略有上升. 这主要可归功于油介质的润滑作用, 由于两个摩擦表面之间润滑油膜的形成, 使得摩擦接触面之间咬合作用受到抑制, 样品表面粗糙度的差异基本未对摩擦磨损结果产生明显影响.

2.4 基底粗糙度对摩损特性的影响

图7所示为不同样品及对偶球的磨损形貌照片. 在干摩擦条件下, 1号、2号样品的平均摩擦系数依然保持在0.1以下, 但已出现了明亮的磨痕, 但薄膜仍未出现分层现象, 对摩的Si3N4球没有明显的磨损, 但球表面有明显转移膜存在, 这是可能是样品能够保持较低摩擦系数的原因. 表面粗糙度较大的3、4号样品的平均摩擦系数开始出现剧烈的波动, 3号样品的平均摩擦系数达到了0.349 0, 4号样品的平均摩擦系数达到了0.413 2, 同时磨损也十分剧烈, 样品表面均磨出了很深的犁沟, 对摩的Si3N4球磨损明显, 球面已磨出了平台. 在油润滑条件下, 样品的摩擦系数均在0.1以下, 1、2号样品的磨损较轻, 样品表面磨痕浅, 薄膜没有出现分层现象, 对摩的Si3N4球几乎没有磨损, 并且球表面也没有出现明显的转移膜. 随着3号、4号样品的表面粗糙度增大, 在试验过程中样品表面的尖峰位置基本被磨平, 有金属基体暴露, 此现象在表面最粗糙4号样品最为明显, 同时4号样品的Si3N4球的磨损量也较3号样品明显增加.

图8是样品在干摩擦条件下磨痕的三维形貌照片. 图9是样品在干摩擦条件下磨痕二维的轮廓曲线. 如图8(a~b), 1号、2号样品的磨损较轻, 磨痕边沿较光滑, 结合图9(a~b), 磨痕宽度在100~110 μm之间, 磨痕深度较浅, 磨痕最深处仅有0.6~0.8 μm. 如图8(c~d), 3号、4号样品的磨损较1、2号样品严重, 表面粗糙度的峰面已被磨平, 磨痕宽度增加显著, 结合图9(c~d), 磨痕宽度均已经接近600 μm, 3号样品磨痕最深处达到2 μm以上, 4号样品的磨损最深处已经超过了4 μm.

对摩痕处进行拉曼光谱分析, 如图10所示. 1号样品的G峰的峰位在1 541 cm–1处, D峰的峰位位于1 365 cm–1处, ID/IG的比值约为1.49, 2号样品的G峰的峰位在1 542 cm–1处, D峰的峰位位于1 367 cm–1处, ID/IG的比值约为1.55. 对比初始的薄膜的1.46变化不大, 说明测试后1、2号样品表面薄膜结构基本没有变化. 3号样品的G峰的峰位在1 546 cm–1处, D峰的峰位位于1 386 cm–1处, ID/IG的比值约为2.22, 说明由于高摩擦系数带来的高摩擦热已经使薄膜出现了明显的石墨化转变. 而4号样品的拉曼光谱形态已不符合类金刚石薄膜的形态, 表明4号样品表面已无碳膜存在.

对照磨损情况可以发现, 基底粗糙度对于薄膜样品磨损性能有重要影响, 特别是对于干摩擦条件下的磨损特性. 在干摩擦条件下, 摩擦接触面受磨料磨损机制控制对表面不平整性引起的机械咬合作用较为敏感. 低粗糙度时候较弱的机械咬合作用使得Cr-DLC涂层自润滑性能得以充分发挥, 薄膜由于兼具较高的硬度而呈现出了良好的耐磨特性, 磨损轻微; 粗糙度增加所引起的机械咬合增强使得Cr-DLC薄膜自润滑性能受到干扰, 薄膜与摩擦对偶之间摩擦剪切作用增强, 磨损加剧. 在油润滑条件下, 由于表面油膜的存在, 油膜润滑作用使得两摩擦接触面之间的剪切作用减弱, 粗糙度增加引起表面微凸体之间的机械咬合作用的增强效果受到了润滑油膜的抑制作用, 摩擦剪切作用变化不大或有轻微增强, 故而使得不同粗糙度样品磨损情况基本相当.

综合摩擦磨损性能研究结果发现, 基底粗糙度对Cr-DLC薄膜油润滑条件下摩擦磨损特性影响较为轻微, 而对Cr-DLC薄膜干摩擦条件下摩擦磨损特性影响较为明显, 这主要是由于油润滑抑制了表面不平整性引起的摩擦接触面机械咬合增强作用, 而干摩擦时候表面不平整性对薄膜摩擦磨损特性影响较大. 基底粗糙度较低时, Cr-DLC涂层干摩擦条件下自润滑减摩抗磨性能得以充分发挥, 可有效保障机械零部件在无油或贫油条件下的稳定工作.

3. 结论

a. 当样品的表面粗糙度为Ra 0.015 μm和0.025 μm时, 在干摩擦条件下, Cr掺杂类金刚石薄膜表现出了良好的自润滑特性样品的平均摩擦系数在0.1以下, 达到了油润滑条件的摩擦水平. 薄膜磨损较小, 磨损表面薄膜结构完整, 磨痕边界光滑, 磨痕宽度100~110 μm, 磨痕最深处仅有0.6 μm, 薄膜未被磨穿.

b. 随着基体表面粗糙度的升高, 当表面粗糙度为0.56和0.78 μm时, 干摩擦条件下的平均摩擦系数上升到了0.3以上, 较低粗糙度样品提升明显. 两个样品均表现出了较为剧烈的磨损, 基体表面磨出了明显的沟槽, 与其对摩的Si3N4球磨损严重. 表面粗糙度在接近Ra 0.8时, 磨痕宽度接近700 μm, 磨痕最深处已超过4 μm, 表面薄膜已被完全磨损.

-

表 1 Cr-DLC薄膜制备工艺

Table 1 Deposition condition of the Cr-DLC film

Coatingprocess Coatingtemperature/ ℃ Total gaspressure /Pa Gas Time/min Plasma cleaning 100 1 Ar 60 Adhesion layer 150 0.3 Ar+N2 60 Inter layer 150 0.4 CH4+ N2 90 Cr-DLC layer 130 0.4 CH4 150 -

[1] Robertson J. Diamond like carbon[J]. Materials Science and Engineering R, 2002, 37(4–6): 129–281

[2] Huaert R. A review of modified DLC coatings for biological applications[J].Diamond and Related Materials, 2003, 12: 583–589

[3] Huaert R. An overview on the tribological behavior of diamond like carbon in technical and medical application[J].Tribology International, 2004, 37(11–12): 991–1003

[4] Gold P W, Loos J. Wear resistance of PVD-coatings in roller bearings[J].Wear, 2002, 253: 465–472

[5] Mutafov P, Lanigan J, A Neville, et al. DLC-W coatings tested in combustion engine-frictional and wear analysis[J].Surface & Coatings Technology, 2014, 260: 284–289

[6] 汪瑞军, 詹华, 李振东, 等. 轴承表面钨掺杂类金刚石薄膜性能研究[J]. 轴承, 2015, (7): 41–44 Wang Ruijun, Zhan Hua, Li Zhendong, et al. Study of properties on bearings coated with tungsten doped diamond-like carbon films[J]. Bearing, 2015(7): 41–44

[7] 詹华, 李振东, 汪瑞军, 等. 硬质合金钻具表面制备W-DLC薄膜性能研究[J]. 新技术新工艺, 2015(6): 122–124 Zhan Hua, Li Zhendong, Wang Ruijun, et al. Study of W-DLC film properties on carbide drill[J]. New Technology & New Process, 2015(6): 122-124

[8] Sánchez-López J C, Fernández A. Doping and alloying effects on DLC coatings. In: Donnet C, Erdemir A. Tribology of Diamond-like Carbon Films[M]. New York: Springer, 2008: 311-338

[9] Yang W, Guo Y C, Xu D P, et al. Microstructure and properties of (Cr: N)-DLC films deposited by a hybrid beam technique[J]. Surface & Coatings Technology, 2015, 261: 398–403

[10] Zhang F F, Krishnaswamy S, Dong F, et al.Ultrasonic characterization of mechanical properties of Cr-and W-doped diamond-like carbon hard coatings[J]. Thin Solid Films, 2006, 503: 250–258

[11] Dai W, Ke P L, Wang A Y. Microstructure and property evolution of Cr-DLC films with different Cr content deposited by a hybrid beam technique[J].Vacuum, 2011, 85: 792–797

[12] 王永欣, 王立平, 薛群基. 金属掺杂高硬度类石墨薄膜结构及其摩擦学性能研究[J]. 摩擦学学报, 2011, 31(1) : 72–77 Wang Yongxin, Wang Lipeng, Xue Qunji.Microstructure and tribological performances of highly hard graphite -like carbon film doped with different metals[J].Tribology, 2011, 31(1): 72–77

[13] T W Scharf, I L Singer. Role of the transfer film on the friction and wear of metal carbide reinforced amorphous carbon coatings during run-in[J]. Tribol Lett, 2009, 36: 43–53

[14] 王佳凡, 王永欣, 陈克选, 等. Cr掺杂对GLC薄膜结构及其摩擦学性能的影响[J]. 摩擦学学报, 2015, 35(2) : 206–213 Wang Jiafan, Wang Yongxin, Chen Kexuan, et al. Effect of Cr doping on the microstructure and tribological performances of graphite -like carbon films[J]. Tribology, 2015, 35(2) : 206–213

[15] Amanov A, Watabe T, Tsuboi R, et al. Fretting wear and fracture behaviors of Cr-doped and non-doped DLC films deposited on Ti-6Al-4V alloy by unbalanced magnetron sputtering[J].Tribology International, 2013, 62: 49–57

[16] Zhang Z X, Dong H, Bell T. The load bearing capacity of hydrogen-free Cr-DLC coatings on deep-case oxygen hardened Ti6Al4V[J]. Surface & Coatings Technology, 2006, 200: 5237–5244

[17] Sun J, Fu Z Q, Zhang W. Friction and wear of Cr-doped DLC films under different lubrication conditions[J].Vacuum, 2013, 94: 1–5

[18] Zou C W, Wang H J, Feng L, et al. Effects of Cr concentrations on the microstructure, hardness, and temperature-dependent tribological properties of Cr-DLC coatings[J]. Applied Surface Science, 2013, 286: 137–141

[19] Jiang J R, Arnell R D. The effect of substrate surface roughness on the wear of DLC coatings[J]. Wear, 2000, 239: 1–9

[20] Harlin P, Carlsson P, Bexell U. Influence of surface roughness of PVD coatings on tribological performance in sliding contacts[J]. Surface & Coatings Technology, 2006, 201: 4253–4259

[21] Lu R G, Zhang H D, Mitsuya Y, et al. Influence of surface roughness and coating on the friction properties of nanometer-thick liquid lubricant films[J]. Wear, 2014, 319: 56–61

[22] Rahaman M L, Zhang L C, Liu M, et al. Surface roughness effect on the friction and wear of bulk metallic glasses[J]. Wear, 2015, 332–333: 1231–1237

-

期刊类型引用(13)

1. 贾伟飞,梁灿棉,胡锋. 高温对含氢DLC涂层的微观结构及力学性能的影响. 表面技术. 2024(05): 174-183 .  百度学术

百度学术

2. 李一治,刘京周,丁子珊,江小辉,郭维诚,鞠鹏飞. 基体表面粗糙度对非晶碳薄膜摩擦磨损性能的影响. 材料保护. 2024(06): 68-73+80 .  百度学术

百度学术

3. 赵凤平,李淑欣,蒲吉斌,王海新,蒋港辉. 马氏体钢表面磁控溅射类金刚石薄膜滚动接触疲劳失效机理. 摩擦学学报. 2022(01): 153-162 .  本站查看

本站查看

4. 任丽梅,高珊,陈兆祥,柴琛,张琛. 自润滑微弧氧化复合膜层研究进展. 燕山大学学报. 2022(02): 104-115 .  百度学术

百度学术

5. 傅文恺,崔学军,杨帆,杨巧玲,张广安. 粗糙度对微弧氧化/类金刚石复合涂层结构及性能的影响. 材料保护. 2022(10): 1-10 .  百度学术

百度学术

6. 肖奕楼,颜培,陈豪,焦黎,仇天阳,王西彬,张宝荣,赵志勇. 基于工艺控制与基体处理的类金刚石涂层性能优化技术研究综述. 润滑与密封. 2021(10): 147-154 .  百度学术

百度学术

7. 向峻伯,王从明,陈凯镔,夏志东,陶沙沙,赵文婕. 汽车发动机用ZL114合金表面涂层制备与性能研究. 真空科学与技术学报. 2019(06): 513-518 .  百度学术

百度学术

8. 陈雪娇,周艳文,徐振,张晶,张豫坤,徐帅,陈星宇. 基底对类金刚石薄膜组织性能的影响. 特种铸造及有色合金. 2019(07): 706-710 .  百度学术

百度学术

9. 李云玉,任西鹏,陈兆祥,李浩,任丽梅. DLC薄膜沉积对不同表面形貌的钛微弧氧化膜层摩擦学性能的影响. 表面技术. 2019(07): 112-121 .  百度学术

百度学术

10. 周泉,丁泽良,王易,张海波,吴发展. Ti6Al4V钛合金表面Ta_2O_5/Ta_2O_5-Ti/Ti多涂层的制备与性能研究. 包装学报. 2019(06): 23-30 .  百度学术

百度学术

11. 詹华,汪瑞军,李振东,王伟平. 边界润滑条件下薄膜碎片对W-DLC薄膜磨损性能的影响. 中国表面工程. 2018(02): 59-65 .  百度学术

百度学术

12. 詹华,汪瑞军,李振东,徐天杨,王伟平. Effects of fragments on W-DLC films properties under boundary lubrication condition in the friction system. China Welding. 2018(02): 31-38 .  百度学术

百度学术

13. 张岩,肖万伸. 类金刚石薄膜微观磨损行为的分子动力学模拟. 材料科学与工程学报. 2018(06): 927-931+940 .  百度学术

百度学术

其他类型引用(14)

下载:

下载: